Zintathu iindidi zeglasi ezisicaba ehlabathini namhlanje: umzobo osicaba, indlela yokudada kunye nekhalenda. Iglasi edadayo, ethatha ngaphezulu kwe-90% yemveliso yeglasi iyonke ngoku, yeyona nto isisiseko sokwakha kwiglasi yezokwakha zehlabathi. Inkqubo yokuvelisa iglasi edadayo yasekwa ngo-1952, emisela umgangatho wehlabathi wemveliso yeglasi ekumgangatho ophezulu. Inkqubo yeglasi edadayo ibandakanya amanyathelo amahlanu aphambili:

● izithako

● ukunyibilika

● ukwenza kunye nokwaleka

● ukucoca

● ukusika nokupakisha

Izithako

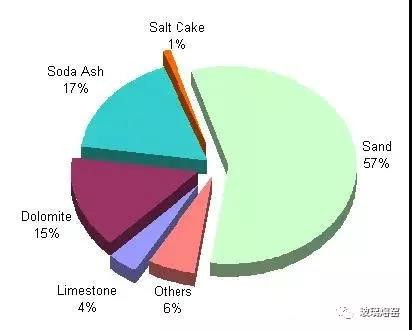

I-Batching yinqanaba lokuqala, elilungiselela izinto eziluhlaza zokunyibilika. Imathiriyeli ekrwada ibandakanya isanti, idolomite, ikalika, isoda ash kunye nemirabilite, ezithuthwa ngelori okanye ngololiwe. Ezi zixhobo eziluhlaza zigcinwe kwigumbi lokudibanisa. Kukho i-silos, i-hoppers, amabhande okuhambisa, i-chutes, abaqokeleli bothuli kunye neenkqubo zokulawula eziyimfuneko kwigumbi lezinto eziphathekayo, ezilawula ukuthuthwa kwezinto eziluhlaza kunye nokuxuba izinto ze-batch. Ukususela kumzuzu ukuhanjiswa kwezinto ezibonakalayo kwigumbi lezinto eziphathekayo, zihlala zihamba.

Ngaphakathi kwegumbi lokudibanisa, ibhanti elide lokuhambisa elisicaba lihlala lithutha imathiriyeli ekrwada ukusuka kwizisele zemathiriyeli ekrwada eyahlukahlukeneyo ukuya kumaleko we-emele ye-elevator ngokomaleko ngokulandelelana, kwaye emva koko izithumele kwisixhobo sokulinganisa ukujonga ubunzima bayo obudibeneyo. Iziqwenga zeglasi ezisetyenzisiweyo okanye iimbuyekezo zemveliso ziya kongezwa kwezi zithako. Ibhetshi nganye iqulethe malunga ne-10-30% yeglasi ephukileyo. Izinto ezomileyo zongezwa kwi-mixer kwaye zixutywe kwi-batch. Ibhetshi exubeneyo ithunyelwa ukusuka kwigumbi lokudibanisa ukuya kwi-silo yentloko ye-kiln ukuze igcinwe ngebhanti yokuhambisa, kwaye yongezwa kwiziko ngesantya esilawulwa ngumxhasi.

Ukuqulunqwa kweglasi eqhelekileyo

Cullet Yard

Yondla izinto ezixutyiweyo ezikrwada kwindawo yokungena yesithando ukuya kuthi ga kwi-1650 Degrees ngeHopper.

Ukunyibilika

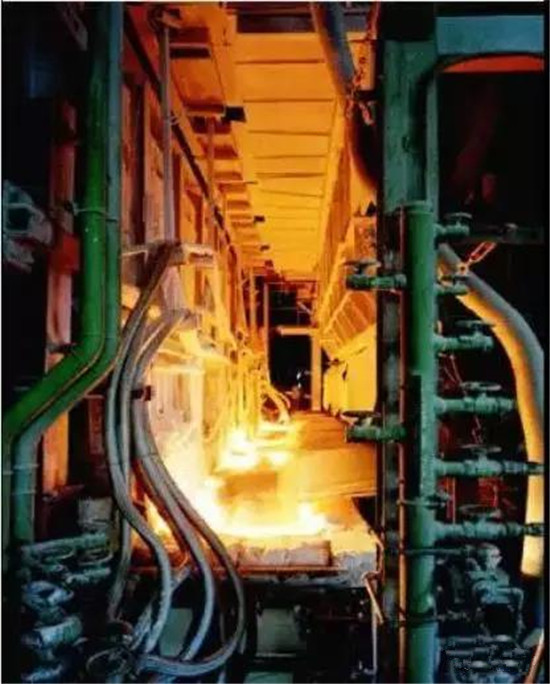

Isithando somlilo esiqhelekileyo sisithando somlilo esinqamlezileyo esinezixhobo ezihlaziyiweyo ezintandathu, malunga neemitha ezingama-25 ububanzi kunye neemitha ezingama-62 ububanzi, kunye nomthamo wemihla ngemihla wemveliso yeetoni ezingama-500. Iindawo eziphambili zesithando somlilo ziyi-melting pool / clarifier, i-pool yokusebenza, i-regenerator kunye nesithando somlilo esincinci. Njengoko kuboniswe kuMzobo 4, yenziwe ngezinto ezikhethekileyo ezichasayo kwaye inesakhiwo sensimbi kwisakhelo sangaphandle. Ibhetshi ithunyelwa kwichibi lokunyibilika leziko ngumxhasi, kwaye ichibi lokunyibilika lifudunyezwa kwi-1650 ℃ ngompu wegesi yendalo.

Iglasi etyhidiweyo igeleza ukusuka kwichibi lokunyibilika ukuya kwindawo yentamo nge-clarifier kwaye ixutywe ngokulinganayo. Emva koko iqukuqela kwindawo yokusebenza kwaye iphole kancinci ukuya kuthi ga kwii-degrees ze-1100 ukuyenza ifikelele kwi-viscosity echanekileyo ngaphambi kokufikelela kwibhafu yetoti.

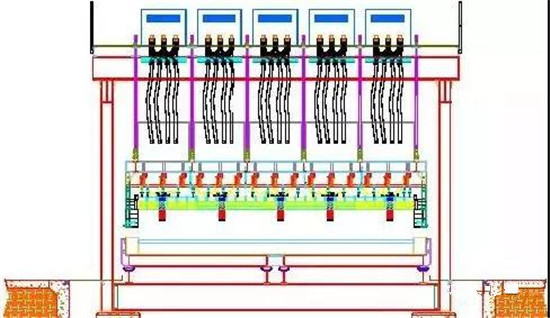

Ukuqulunqa kunye noKwaleka

Inkqubo yokwenza iglasi yeglasi ecacileyo yeglasi kwisitya seglasi yinkqubo yokuguqulwa komatshini ngokwendlela yendalo yezinto eziphathekayo, kunye nobukhulu bendalo balo mbandela ngu-6.88 mm. Iglasi yolwelo iphuma eziko idlula kwindawo yomjelo, kwaye ukuhamba kwayo kulawulwa ngucango oluhlengahlengiswayo olubizwa ngokuba yinkunzi yegusha, emalunga ne-± 0.15 mm nzulu kwiglasi engamanzi. Idada kwitoti etyhidiweyo- yiyo loo nto kuthiwa yiglasi edadayo. Iglasi kunye ne-tin azihambisani kunye kwaye zinokwahlulwa; Ukuchasana kwabo kwimo yemolekyuli kwenza ukuba iglasi ibe lula.

Ibhafu yiyunithi etywinwe kwi-nitrogen elawulwayo kunye ne-hydrogen emoyeni. Ibandakanya ukuxhasa intsimbi, amaqokobhe aphezulu nasezantsi, ii-refractories, i-tin kunye nezinto zokufudumeza, ukunciphisa umoya, izinzwa zobushushu, inkqubo yokulawula inkqubo yekhompyuter, malunga neemitha ezi-8 ububanzi kunye neemitha ezingama-60 ubude, kunye nesantya somgca wemveliso sinokufikelela kwiimitha ezingama-25 / ngomzuzu. Ibhafu yenkcenkce iqulethe malunga neetoni ezingama-200 zetoti esulungekileyo, enobushushu obuphakathi kwama-800 ℃. Xa iglasi isenza umaleko obhityileyo ekupheleni kwendawo yokuhlambela yenkcenkce, ibizwa ngokuba yipleyiti yeglasi, kwaye uthotho lweetsali ezilungelelanisiweyo zisebenza macala omabini. Umsebenzisi usebenzisa inkqubo yokulawula ukuseta isantya se-annealing kiln kunye nomatshini wokudweba edge. Ubukhulu bepleyiti yeglasi bunokuba phakathi kwe-0.55 kunye ne-25 mm. Inxalenye ephezulu yokufudumeza isetyenziselwa ukulawula ubushushu beglasi. Njengoko ipleyiti yeglasi iqhubeka ihamba kwibhafu yetoti, ubushushu beglasi yeglasi buya kuhla kancinci, nto leyo eyenza ukuba iglasi ibe mcaba kwaye ihambelane. Ngeli xesha, i-acuracoat ingasetyenziswa ® Kwi-line plating yefilimu ebonakalisayo, ifilimu ephantsi, ifilimu yokulawula ilanga, ifilimu ye-photovoltaic kunye nefilimu yokucoca ifilimu kwi-pyrolysis CVD izixhobo. Ngeli xesha, iglasi ilungele ukupholisa.

Bath Cross Section

Iglasi isasazeke ibeyiNkonkxa eNcinci kwitoti etyhidiweyo, igcinwe yahluliwe kwitoti, kwaye yenziwe kwipleyiti.

Isixhobo sokufudumeza esijingayo sibonelela ngobushushu, kwaye ububanzi kunye nobukhulu beglasi bulawulwa ngesantya kunye ne-angle ye-edge puller.

Ukuhlaziya

Xa iglasi eyenziweyo ishiya ibhafu yetoti, ubushushu beglasi bungama-600 ℃. Ukuba ipleyiti yeglasi ipholile kwi-atmosfera, umphezulu weglasi uya kuphola ngokukhawuleza kunobungaphakathi beglasi, okuya kubangela ukuxinzezeleka okunzulu komphezulu kunye noxinzelelo oluyingozi lwangaphakathi kwipleyiti yeglasi.

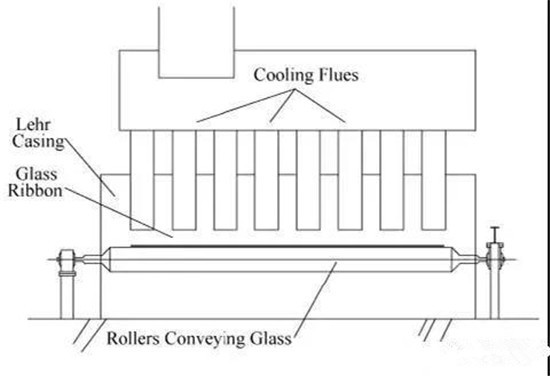

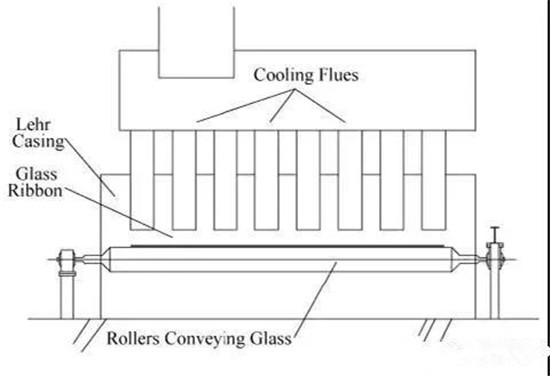

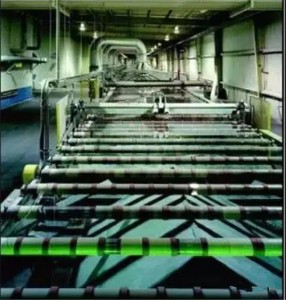

Icandelo le-Anealing Kiln

Inkqubo yokufudumala kweglasi ngaphambi nangemva kokubunjwa kwakhona yinkqubo yokwakheka koxinzelelo lwangaphakathi. Ngoko ke, kuyimfuneko ukulawula ukushisa ukunciphisa ngokuthe ngcembe iqondo lokushisa kweglasi kwiqondo lokushisa eliphantsi, oko kukuthi, i-annealing. Enyanisweni, ukufakwa kwe-anneal kwenziwa kwi-annealing kiln yokushisa esele imiselwe (jonga uMfanekiso 7) malunga neemitha ezi-6 ububanzi kunye ne-120 yeemitha ubude. I-annealing kiln ibandakanya izinto zokufudumeza ezilawulwa ngombane kunye neefeni ukugcina ukuhanjiswa kobushushu obunqamlezileyo beepleyiti zeglasi kuzinzile.

Isiphumo senkqubo ye-annealing kukuba iglasi ipholile ngononophelo kwiqondo lokushisa ngaphandle koxinzelelo lwexeshana okanye uxinzelelo.

Ukusika kunye nokuPakisha

Iipleyiti zeglasi ezipholileyo nge-annealing kiln zithuthelwa kwindawo yokusika ngetafile ye-roller edityaniswe nenkqubo yokuqhuba ye-annealing kiln. Iglasi idlula inkqubo yokuhlola kwi-intanethi ukuphelisa naziphi na iziphene, kwaye inqunywe ngevili lokusika idayimane ukususa umda weglasi (i-edge material iphinda isetyenziswe njengeglasi ephukileyo). Emva koko yinqumle kubungakanani obufunwa ngumthengi. Umphezulu weglasi ufafazwe ngepowder medium, ukwenzela ukuba iipleyiti zeglasi zifakwe kwaye zigcinwe ukuphepha ukunamathela kunye okanye ukukrwela. Emva koko, iipleyiti zeglasi ezingenasiphako zihlulwe zibe yimfumba yokupakishwa ngoomatshini bezandla okanye abazenzekelayo, kwaye badluliselwe kwindawo yokugcina impahla yokugcina okanye ukuthunyelwa kubathengi.

Emva kokuba i-Glass Plate ishiya i-Annealing Kiln, i-Glass Plate yenziwe ngokupheleleyo kwaye ihanjiswe kwindawo yokupholisa ukuze iqhubeke nokunciphisa iqondo lokushisa.